Our product family, the Modulusz 50 door and partition wall building system, was tested for acoustic performance by a third-party NAH and CERTOP accredited laboratory. The tests included hinged doors, sliding doors, and glass partition walls.

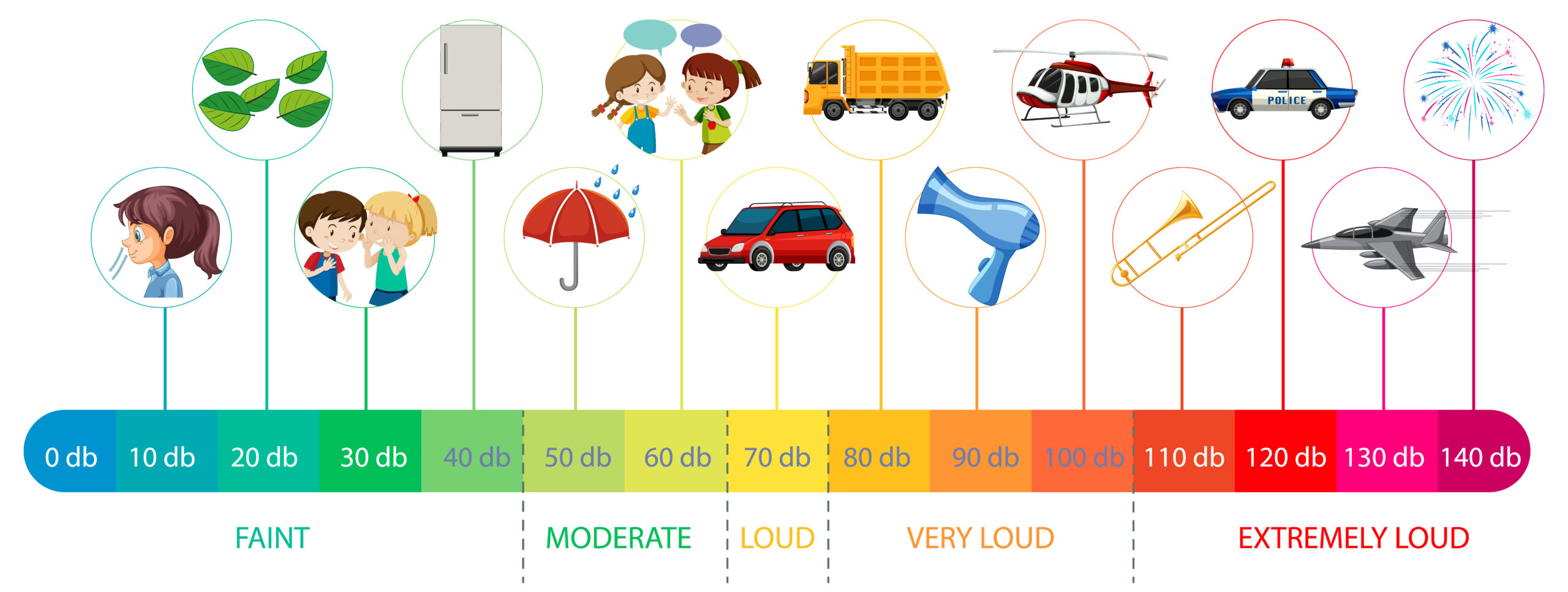

Important to mention that a door or window’s acoustic performance or airborne sound-reduction capability is expressed in dB. The higher the value, the better the soundproofing of the door or window.

An interesting little point: the dB scale below shows what a noise reduction of, e.g. 40 dB, means. If a speaking pitch is around 60 dB and the noise level of cars is about 70 dB, these products with 30 to 40dB performance can reduce it to a sound level of 20 dB and 30 dB, respectively, equal to the noise level of whispering.

MAIN CHARACTERISTICS OF OUR PRODUCTS:

NARROW, MODERN DESIGN + EXCELLENT SOUNDPROOFING

It is usually hard to achieve a good soundproofing performance with a narrow profile design; therefore, it is essential already at the design phase to analyse and design the system accordingly. Our design phase includes putting these two characteristics in the foreground, i.e. narrow, modern design and good soundproofing capability. Moreover, our aluminium profile system is supplied with a silicone gasket to achieve even better soundproofing.

QUALITY + ENVIRONMENT

Our products are extruded of high-quality ‘marine’ grade aluminium. In addition, 50% of the aluminium material is recycled, which is unique on the market. When testing, this was the crucial percentage at which we could maintain the aluminium’s quality and mechanical properties. Moreover, most plastic components are recycled, making our product family’s ecological footprint significantly smaller than other similar products.

TEST PROCESSES:

Our products were tested in the central laboratory of ÉMI in Szentendre.

A sound test measures the resistance to the passage of airborne sound through a separating window, partition wall or door. In general, the test is made by using a loudspeaker placed outside the measured room, where the speaker produces a steady level of pink noise (since pink noise consists of an even level of sound in all frequencies). On one side, the loudspeaker generates a noise pitch of 105 dB; on the other side of the specimen, a special microphone measures the acoustic emissions. In addition, the speakers are re-positioned so that the soundwaves can reach the specimen from different angles.

The tested doors and glass walls are fitted with different types of glass, dividers, silicone and rubber gaskets, locks, and handles to provide more variations for customer use.

For a better result, generally smaller, standard-size doors (e.g. 2100 x 850) are tested, as the larger the door, the more difficult it is to achieve good sound insulation. To prove that our products are efficient, we tested only sizes larger than the standard, as the primary target groups of our Modulusz product family include loft apartments and offices with higher ceilings. As a comparison to our test results of 30 to 41dB, a standard door performs between 20 and 30 dB.

ACOUSTIC RESULTS:

Our products achieved results between 30 dB and 41 Db of sound-reduction, depending on:

- what type of glass was used for testing (tempered 8mm, tempered 10mm, sound-laminated size 8.76mm or sound-laminated size 10.76mm)

- standard fixed or automatic threshold installed (the latter has better insulation and is fully accessible)

- the lock is a roller catch type or a mortise latch lock (the latter gives better insulating performance)

TESTED MODULUSZ 50 PRODUCTS:

Hinged door:

- size: 2380 x 1150 mm, rosette door-handle, mortise lock, from 30 dB to 40 dB

- size: 2380 x 1150 mm, push-pull handle, mortise roller catch lock, from 32 dB to 36 dB

- size: 2380 x 1150 mm, two pcs of horizontal dividers, transoms, push-pull handle, mortise roller latch lock, from 30 dB to 35 dB

Sliding door:

- size: 2365 x 1150 mm, push-pull handle, gravity lock developed by XS-ALU, from 30 dB to 40 dB

Partitioning glazed wall:

- full size: 4210 x 2722 mm, from 31 dB to 41 dB

- first glass wall size: 1500 x 2722

- second glass wall size: 1180 x 2722 with one piece of a vertical divider, mullion

- third glass wall size: 1500 x 2722 with two pieces of horizontal dividers, transoms

Compared to other products, an average internal door does not even have measurement data, while a better quality and branded interior door achieve between 20 and 30 dB in standard size (2100×850).