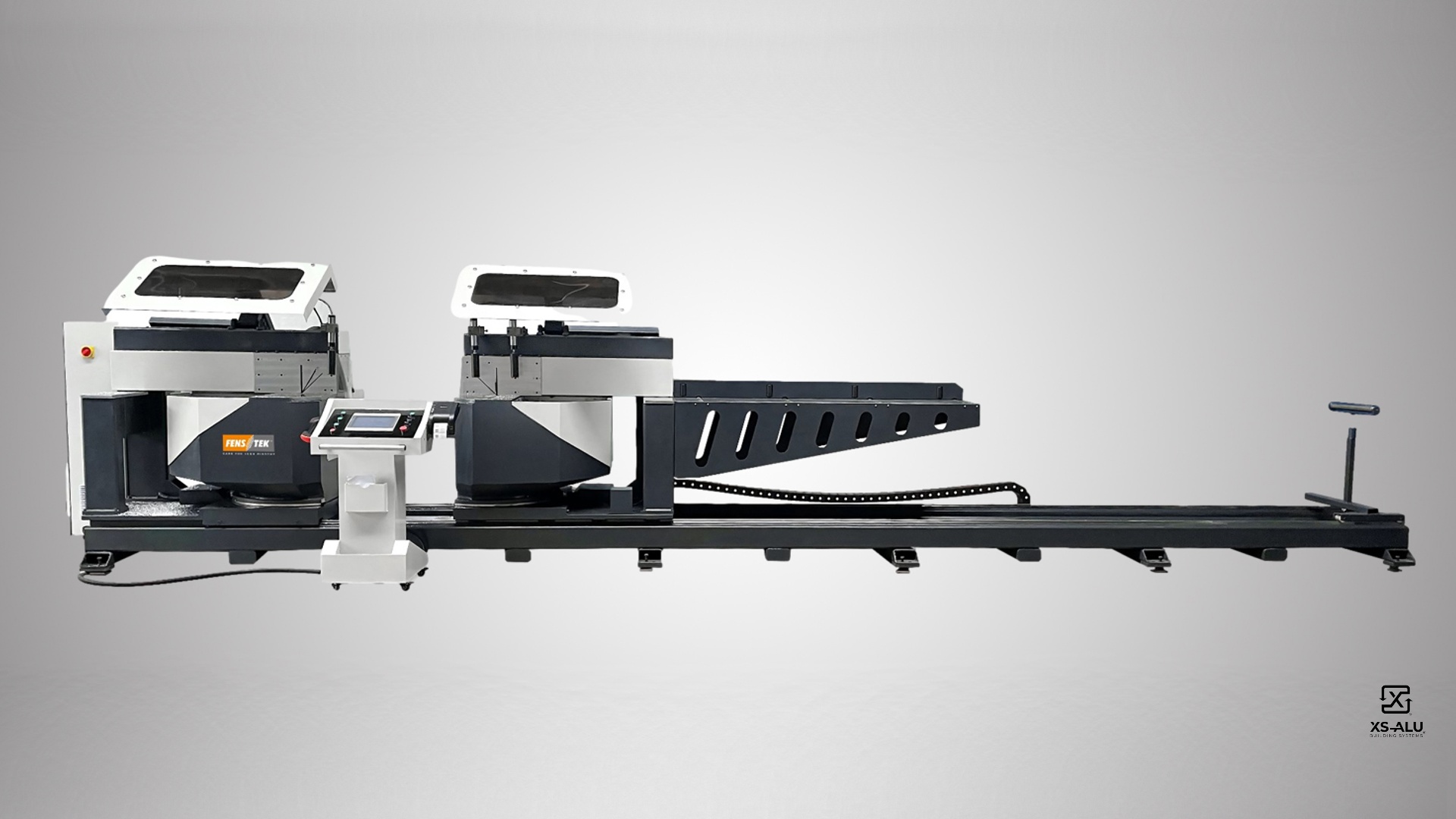

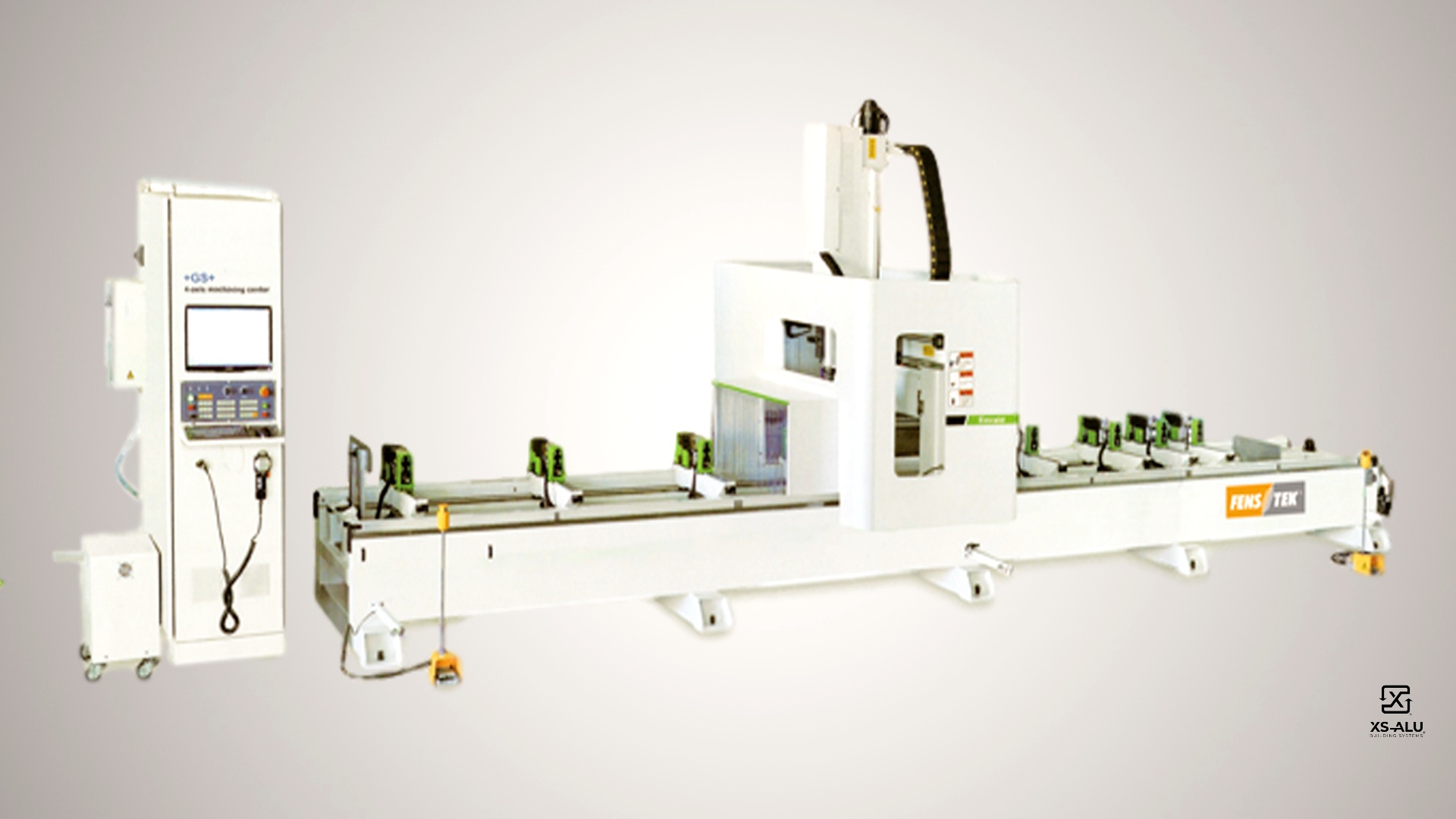

Whether for window, door or façade fabrication, the Emerald F260, with processing lengths of 7.0 meters or excess lengths in double working zones, with 3-sided processing, serves almost every task in the fenestration fabrication with its 4-axis gantry type CNC.

Features:

- Suitable for aluminium profile and other light alloys, as well as UPVC profile processing

- 4-axis machining, with a head axis from 90 ° to -90 ° at any position

- Completes milling, drilling, flexible tapping, grooving, steel drilling (within 3 mm) and other multi-functional precisely in one time

- Profiles hold by automatic precision clamps to avoid profile damage

- Smooth motion via high-precision HIWIN linear guideways, PMI ball screws, APEX racks and YASKAWA servo motor

- High-quality automatic tool change with 9-tool magazine

- Double working areas for quicker processing, milling one after another, interactive feeding with non-interference

- Multiple safety protection devices to ensure operator safety

- Included UPS & AC for protecting the operation system

- Automatic processing with optional CamQuix software and ERP with code scanning

- Gantry type structure for high stability and rigidity

- Included UPS & AC for protecting the operation system